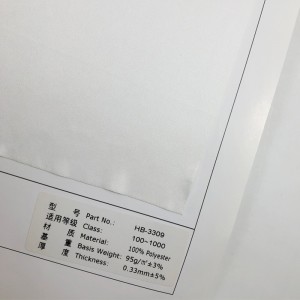

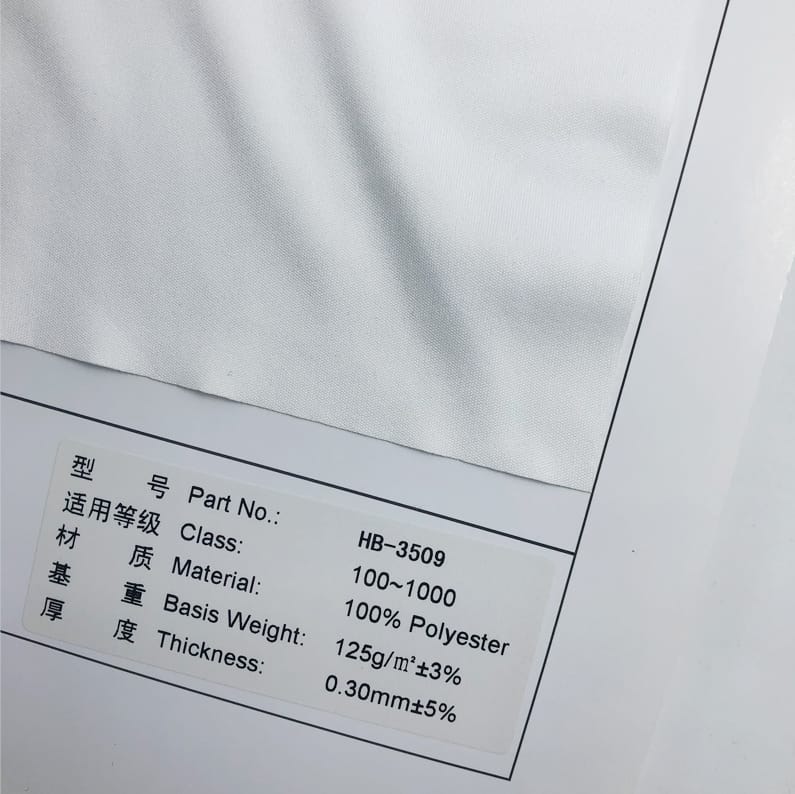

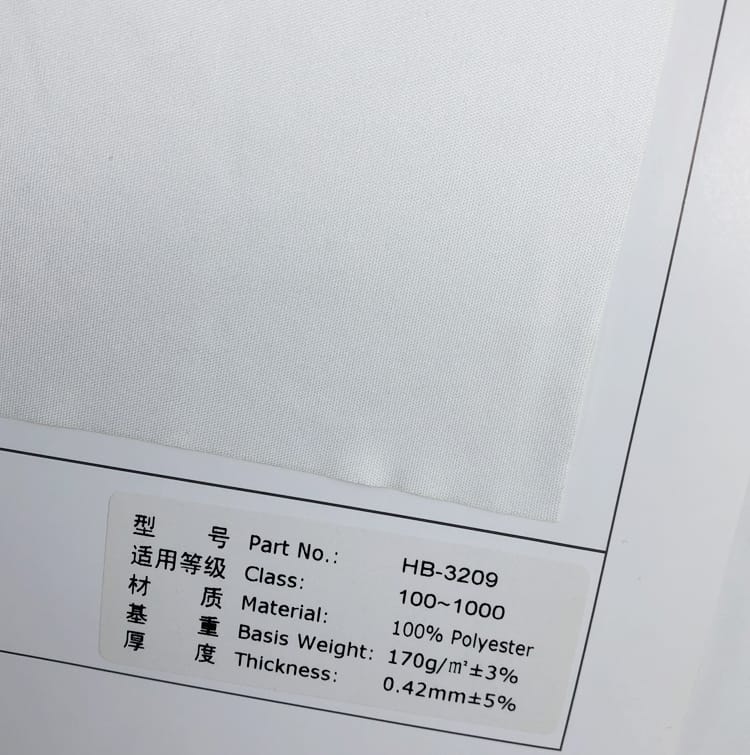

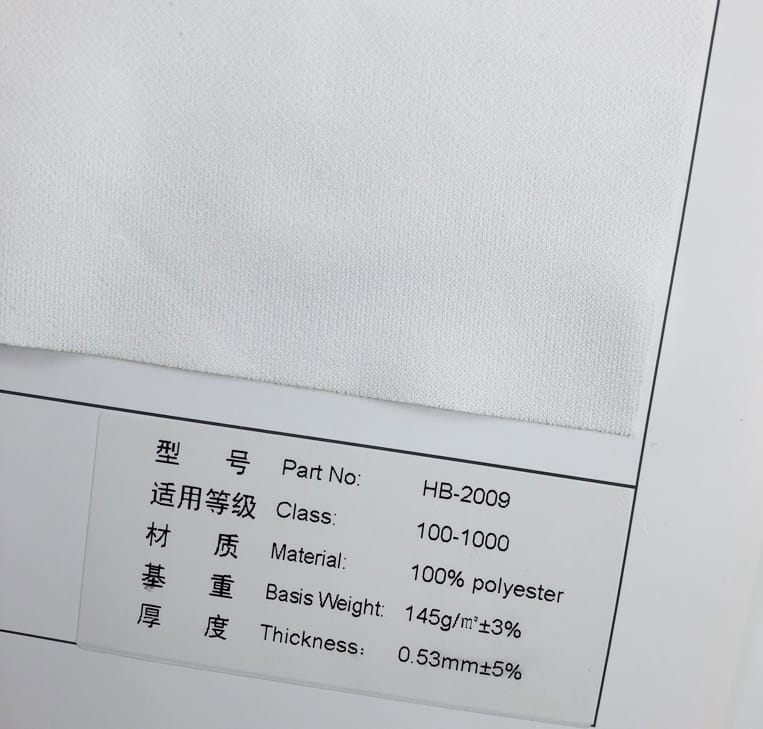

Hot selling 110-170gsm clean room wiper factory supply 100% polyester cloth lint free cleanroom wiper

Product Process

1. Spining:Double A fixed length DTY low elastic wire, Continues fiber, super soft,No silicon.

2. Weaving:Rich Weaving method , Different model weaving machine can choose. Perfect quality control, regular equipment maintenance, standardized process control.

3. Cleaning:Separate grey cloth cleaning, 18MΩ pure water cleaning, sewage treatment unit saves cost.

4. Dyeing:Specially designed for dust-free cloth-setting equipment, indirect heating systems, stable and controlled process specifications, providing clean, low-ion

contamination, bottom NVR fabrics.

5.Fabric : Double layer packaging Clean dust protection

6. Cutting : Ultrasonic/Laser cutting

Features:

• Cleanroom laundered and packaged providing ultra low levels of ions and non volatile residues.

• Designed for use on abrasive surfaces. This wipe will not easily snag or abrade releasing articles and fibers into the process

or environment.

• Excellent chemical resistance for compatibility with a variety of solutions.

• Individually lot coded for ease of trace-ability and quality control.

• Good absorption with water and solvents.Hold more dirt and residues than average wipe. Remove residues from the surface more

effectively.

Application

Electronic Manufacturing and Assembly Industry:Serves as the core cleaning consumable for consumer electronics and industrial electronics production lines, used to wipe dust, fingerprints, and residual flux from printed circuit boards (PCBs), electronic components, display screens (LCD/LED panels), and touchscreen surfaces.

Suitable for assembly processes of smartphones, computers, tablets, and smart home devices, it minimizes lint shedding and secondary contamination after wiping, preventing impairment of electronic components' conductivity and product yield rates.

Semiconductor and Photovoltaic Industry :It can be used for surface dust removal and cleaning of photovoltaic cells and silicon wafers, eliminating microscopic particles and oil residues adhering during production to ensure the photovoltaic conversion efficiency of cells.

During semiconductor packaging, it can wipe chip pins and packaging casings while removing residual photoresist with solvents, meeting the high cleanliness standards of semiconductor devices.

Precision Instrument and Equipment Maintenance

Suitable for daily cleaning of laboratory analytical instruments (e.g., chromatographs, microscopes) and measuring devices (e.g., calipers, projectors). Wipes lenses, control panels, and precision components to prevent dust from affecting instrument accuracy.

Suitable for surface cleaning of industrial automation equipment (e.g., robotic arms, sensors), removing oil residue and dust generated during operation to extend equipment lifespan.

Automotive Electronics and Precision Component Manufacturing

Cleans electronic components like in-vehicle displays, central control systems, and sensors. Also removes dust from precision automotive parts (e.g., engine fuel injectors, transmission valve bodies), meeting automotive manufacturing cleanliness requirements.

Printing and Digital Imaging Industry

Removes ink residue and dust from printer nozzles and printing plates to prevent nozzle clogging and plate contamination, enhancing print clarity and yield rates.

Compatible with UV printing and digital textile printing equipment maintenance to prevent impurities from affecting print quality.

Workplace Safety & Cleanroom Daily Cleaning

In cleanrooms and dust-free environments, used to wipe dust from workbenches, walls, and floors. Can be combined with disinfectant solutions for surface sterilization to maintain cleanroom classification standards.

Serves as a cleaning consumable for operator hands and tools, compliant with cleanroom operational protocols.

Picture

Payment terms: 30% deposit, 70% before shipment;

Samples: Free samples are available, freight collect payment

Lead time: 7-10days

MOQ: 10cartons, price depends on the quantity.

Port of departure: Shanghai China