In precision industries like electronics, semiconductors, chips, and LCD manufacturing—where cleanliness and quality are critical—hand protection directly affects yield and efficiency. Lijie’s new 12-inch Class 1000 nitrile gloves (L62T) cut costs by 10% while ensuring consistent quality, helping enterprises truly reduce costs and boost efficiency.

I. Exceptional Clean Processes, Strict Quality Control

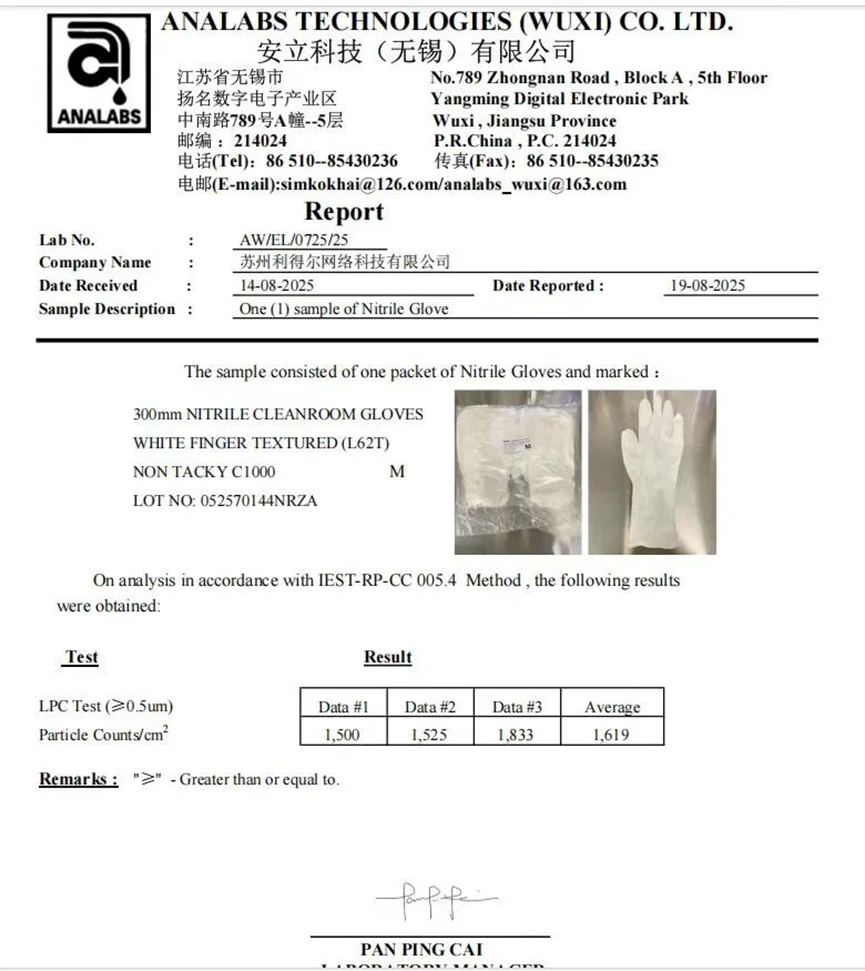

The new Lijie clean 12-inch Class 1000 nitrile gloves (L62T) feature proprietary ‘dual chlorine washing + DI water rinsing’ technology, with over 8 cycles of cleaning using 18 MΩ water. Strict control keeps LPC below 2000—far lower than the Class 1000 limit of 3500—while ensuring ‘fingerprint-free’ performance. This minimizes defects in ultra-precise components like chips and LCD panels, providing reliable protection for high-cleanliness manufacturing.

II. Premium Materials, Contoured Design for Cleanliness

The 12-inch Class 1000 nitrile gloves (L62T) are made of high-purity nitrile rubber, eliminating latex allergy risks while offering superior puncture and chemical resistance. Their extended 12-inch length ensures full wrist-to-forearm coverage, reducing contamination risks. Optimized finger texture doubles durability, enhances grip on millimeter-scale components, and improves stability and precision, lowering error rates.

III. Full-Process Quality Control and Strict Compliance

Lijie Clean regards quality as its lifeline. The 12-inch Class 1000 nitrile gloves (L62T) follow strict international standards from raw materials to shipment, ensuring full traceability. RoHS-compliant with low chemical and non-volatile residues, they prevent corrosion and performance issues in precision products, safeguarding production safety and stability.

IV. Widespread Adoption and Recognition by Industry Leaders

Widely adopted in electronics, semiconductors, chips, LCD panels, and precision instruments, the L62T 12-inch Class 1000 nitrile gloves have earned recognition from industry leaders, including SMIC, BOE, Foxconn, O-Film, and Huatian Technology. In processes like wafer cutting, chip packaging, testing, and LCD production, L62T boosts yield with its low residue, high cleanliness, and excellent operability—preventing display defects and supporting ‘zero-defect’ manufacturing. Offering consistent quality with 10% lower cost, L62T provides a reliable, cost-effective protection solution that enhances efficiency, competitiveness, and high-quality growth in precision manufacturing.

Post time: Sep-10-2025